Well, kadang gue suka lupa standar stair, maka disini gue bakalan share sekaligus buat remind me dikala lupa. Berikut adalah Standar Stair yang gue sadur dari AISC (American Istitute of Stell Construction).

Sorry juga nih bahasanya di mix Prinsip Dasar Detailing Stair:

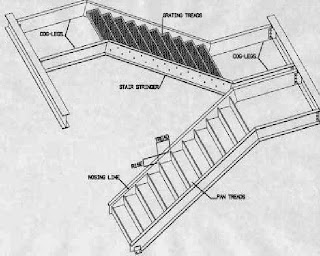

STRUCTURAL STEEL COMPONENTS.

Tread: The tread is the piece of steel

that makes up the steps of the stair.The tread can be made from grating or

from pans (both shown in Figure 1).

Grating is typically used in industrial

buildings while pans are usually used in

commercial structures. The grating type

of tread is plate, but the pan shape dips

down so that the concrete can be poured

into its base.

Sanitary-type pans, which are common

in hospitals, have an additional lip

that prevents dirt from falling into the

corner of the pan.

(Pan and grating treads are shown in

Figure 2.)

Stringers: The stringers support the

ends of the treads. Stringers are often

rectangular hollow sections, channels or

plate. The top of the stringer is connected

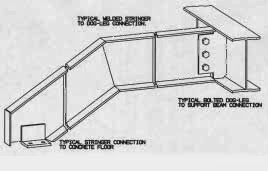

either to a supporting beam or to a dog leg (see Figure 3).

The bottom of the stringer is connected

to a supporting beam, a dog leg, or

the ground. If attached to a supporting

beam, the stringer can be bolted or

welded. If attached to a dog leg, the

stringer will be welded.

Supporting Beam: The supporting

beam supports the stringer or the dog

leg (if it exists). Each stringer can be

independently supported. Alternately,

both stringers can be supported with

the same supporting beam. The supporting

beams are usually wide flange

sections or channels.

Dog legs: The location of the supporting

beams determines whether dog legs

are actually needed (as shown in Figure

4). A dog leg is needed when a viable

connection cannot be made to the supporting

beam directly from the stringer.

The dog leg can be the support for the

landing at the top of the stair, if one

exists.

Special pans: These are required at

the top and bottom of a pan stair. One

special pan closes the stair against the

concrete or platform, and the other pan

closes off the top of the stair (see Figure

5).

LOCATION

The main parameters for

locating the stairs are:

• Rise and tread

• Nosing points and nosing line

• Stringer offset values

• Dog leg to nosing point height

• Safe rise and safe run

• Number of treads

An explanation of these terms

follows:

Rise and tread: Although the

actual stair step is called the

tread, there is also a measurement,

as shown in Figure 1,

which is termed the 'tread'. This

is the horizontal distance

between two consecutive treads.

The rise is the vertical distance

between two consecutive treads.

Nosing line and nosing

points: In order for the stair to

be set up properly, every corner

of every tread should pass

through a single line. That line

is called the nosing line, and the

corner points on the tread

through which the line traverses

are called the nosing points.

Stringer offset value (top of

steel of stringer to nosing

line): As shown in Figure 6, the

stringer offset is the perpendicular

distance between the top of

steel of the stringer and the nosing

line. The stringer offset

value is required for locating the

stringer in space.

Dog leg to nosing point

height: Where dog legs are

required (i.e. cases where the

stringer can't directly make a

viable connection to the supporting

beam), it is necessary to

locate the dog legs. The top dog

leg to nosing point height is the

distance from the top nosing

point to the top of steel of the top

dog leg. The bottom dog leg to

nosing point height is the distance

from the bottom nosing

point to the top of steel of the

bottom dog leg.

Safe rise and safe run: The following

general guidelines are

typically used for indoor stairs in

insuring that the stair is safe:

• 3/16 maximum variation in rise

or tread is allowable.

• 2 x rise + tread should be

between 24” and 25”.

• Rise + tread should be

between 17” and 171/2”.

• Angle of the stair should be

between 20 and 50 degrees.

Note: tread minimum and rise

maximum, as well as other

important parameters are governed

by local or state codes.

Number of treads: The number

of treads is obtained by dividing

the total rise by the safe rise, or

alternately by dividing the total

run by the safe run.

CONNECTIONS

Grating to stringer: A typical

grating to stringer connection is

shown in Figure 7. The grating

manufacturer specifies the location

of the bolt holes.

Pan to stringer: A typical pan

to stringer connection is shown in

Figure 7. Other connection types

include double angles with a

square rod bent around the pan

and welded to both the pan and

the stringer.

Stringer to dog leg: A common

stringer to dog leg connection is

shown in Figure 3. This is a

welded connection with both

ends mitered.

Stringer to ground: A common

stringer to concrete floor connection

is shown in Figure 3.

Sekian dulu yaaa, buat standar koneksinya i'll be back soon :D so you better keep watching